VLS Desktop 3.50

| Work Area | 610 x 305 mm |

| Laser Options | 10, 25, 30, 35, 40, 45- 50 Watts |

|

Specifications |

VLS 3.50 |

| Work Surface Area | 609 x 305 mm |

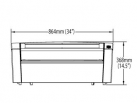

| Maximum Part Size | 679 x 368 x 102 mm |

| Maximum rotation | Ø127 mm, h453 mm |

| Dimensions | 863 x 355 x 635 mm |

| Laser Options | 10, 25, 30, 35, 40, 45 - 50 watts |

| Approximate Weight | 43 kg |

| Power Management | 0 - 100% step 0.1% |

| Speed control | 0.1 - 100% step 0.1% |

| Resolution | 1000 dpi |

| Available Focus Lenses | 1.5”(38 mm)*standard 2.0”(51 mm), HPDFO™(0.023 mm) |

| Precision repeatability | 0.002 mm |

| Operating temperature | 10 - 35°C |

| Operation | Vector, raster, 3D, clip-art, rubber stamps mode |

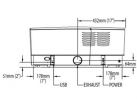

| Operating System Compatibility | USB 2.0, Windows XP / Vista /Windows 7 |

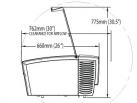

| Exhaust Connection | 425 m3/hr at 1.5 kPa |

| Get your offer now >> |

|

Rotary Fixture

|

|

Downdraft Cutting Table This accessory provides a raised platform of honeycomb material to support materials for cutting applications. Exhaust smoke and fumes are removed from above and below the material being cut, keeping the material clean and producing better cuts. |

|

Pin Table The Universal Pin Table is designed to eliminate certain scorch marks and other defects which may occur when cutting acrylic, wood or other sensitive materials using conventional laser cutting tables. |

|

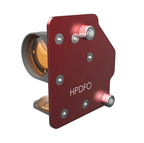

HPDFO™ High Power Density Focusing Optics. These optics focus the laser beam to a much smaller focal spot, producing a sharper, tighter tolerance image. Requires Collimator |

|

Also known as a beam expander, the Collimator expands and collimates the beam to minimize divergence and provide an unchanging focal spot across the engraving field. This results in more consistent cutting and engraving from one corner of the engraving field to the other. Required for HPDFO |

|

Focus lenses 1.5”, 2.0”, 2.5", 3.0", 4.0" Each machine Universal is standard equipped with a 2.0 "lens, which is the most used.To achieve the best results when engraving or cutting material should be in focus. |

|

Back Sweep The Back Sweep accessory attaches to the carriage for use in air assisted applications. It directs compressed air onto the material at an angle to the laser beam. |

|

Air Assist Cone The Cone accessory attaches to the carriage for use in air-assisted applications. It directs compressed air along the beam path (coaxially) and onto the material. |

|

Compressed Air Source This accessory provides a clean, water- and oil-free source of optical quality compressed air for use in air-assisted laser processing applications. |

|

This air filtration device removes smoke and fumes when external venting is not possible. The cart is controlled through a USB port and automatically powers on/off when a job is in process.

|

|

Automation Interface This interface makes it possible to integrate a Universal laser system into an automated manufacturing cell. |

|

Universal Laser Sources Our exclusive line of patented CO2 Free-Space Gas Slab Lasers is designed specifically for the needs of laser cutting, engraving, graphic imaging and marking applications. |

|

Density -Focusing Optics These optics allow the laser beam to be focused to a much smaller spot, producing sharper images at tighter tolerances. |

|

Laser Interface+ The world's most advanced, powerful and flexible laser print driver for material processing systems. Laser Interface+ is a materials-based print driver that gives you the choice of automatic or manual control over power, speed, pulses per inch and other system settings. Laser Interface+, combined with the Universal Control Panel (UCP), gives you complete control over your laser processing system. |

|

1-Touch Laser Photo We developed this software to make any photographic image suitable for laser engraving. Simply select your target material from a list and 1-Touch Laser Photo will determine the appropriate contrast, filter and grayscale levels and calculate the ideal laser speed and power settings. Then engrave the image onto your material at the touch of a button. |

| Metals Laser marking is a very precise and clear process for handling metal.Markiraneto serial numbers, codes and logos on products and parts is a contactless process ......... |

| Crystal & Glass Processing of glass engraving possible complex forms and photographic images directly on wine glasses, beer bottles, windows, mirrors .......... |

| Wood Laser cutting and engraving of wood guaranteed to perform with smooth edges and high speed production. This is guaranteed even if production of complex parts and shapes, regardless of their size .......... |

| Plastic When laser cutting acrylic, the result depends on various components .............................. |

|

For laser engraving rubber stamps, the text must be mirrored and inverted. This is done automatically by Trotec JobControl. And using the JobCreator, type-setting for the rubber stamp is even easier...... |

| Paper & Cardboard Laser cutting is a quick and easy process that can be used for processing paper, paperboard and cardboard for digital printing, for packaging prototype construction, model making or scrapbooking....... |

| Stone Laser engraving on stone offers incredible design options. With a laser engraving machine from Trotec, even detailed photographs and graphics can be realized....... |